.gtranslate_wrapper

Understanding Laser Cutting Machine Software Control Systems

Laser cutting technology has revolutionized manufacturing by offering high precision, speed, and versatility. However, the true power of a laser cutting machine lies not only in its hardware but also in its software control system. This system acts as the brain of the operation, ensuring the machine performs efficiently and accurately across different materials. In this blog post, we’ll explore the key aspects of laser cutting machine software systems and how they enable precise and reliable cutting operations.

What is a Laser Cutting Machine Software System?

A laser cutting machine software system is responsible for controlling the movement of the laser head, adjusting the laser’s power, and managing all machine functions. It is the intermediary between the machine’s physical hardware and the operator’s design instructions. The software ensures that the laser beam is directed with high precision according to the design specifications and material types.

Key Components of Laser Cutting Machine Software Control

1. CNC Control System (Computer Numerical Control)

The CNC control system is the core of laser cutting machine software. It converts design files, usually from CAD (Computer-Aided Design) software, into machine-readable instructions. The CNC system guides the laser’s movements, adjusts speed, power, and trajectory to ensure precise cuts.

Functions:

- Path Planning: The software calculates the most efficient cutting path based on the design.

- Motion Control: Ensures precise movement of the laser head along the X, Y, and Z axes.

- Laser Power and Speed Adjustment: Automatically adjusts the laser’s intensity and cutting speed based on material and thickness.

- Cutting Sequence: Organizes the order of operations to minimize cutting time and material waste.

2. CAM Software (Computer-Aided Manufacturing)

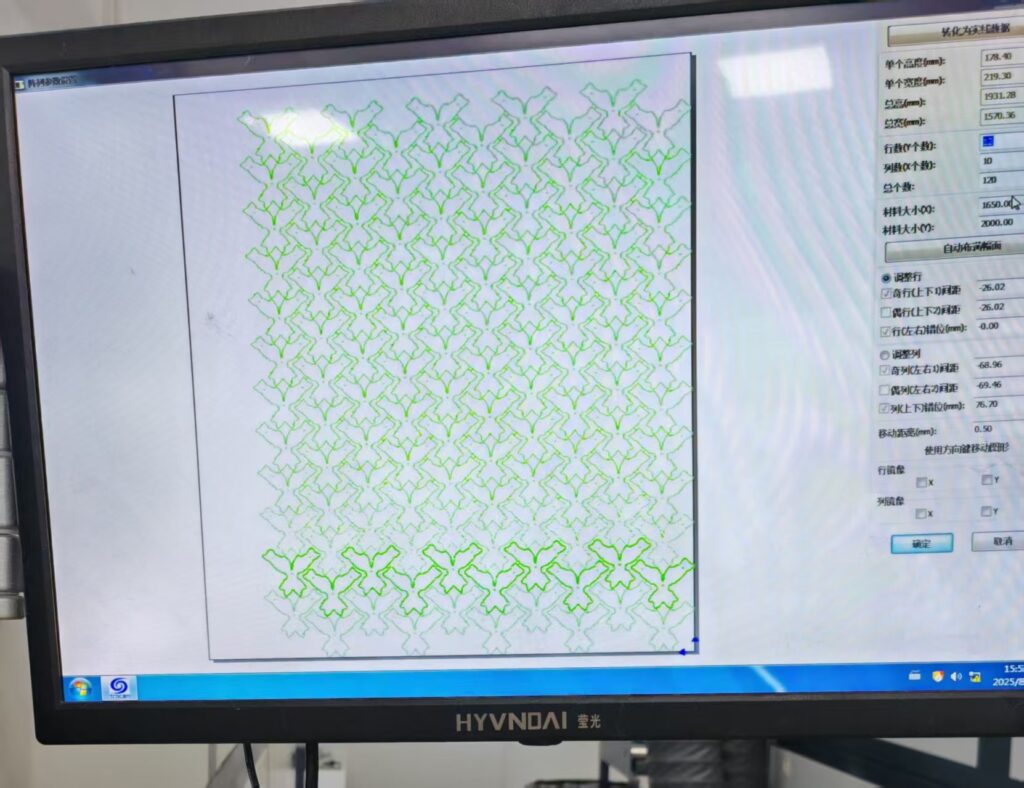

CAM software takes the design data from CAD software and translates it into machine-readable instructions that control the laser cutting process. CAM software is vital for optimizing cutting paths and ensuring that the machine operates at maximum efficiency.

Functions:

- Path Generation: Converts design files into cutting paths for the laser cutter.

- Material Optimization: Adjusts cutting parameters (laser power, speed) based on the material being cut, ensuring quality cuts.

- Simulation: Simulates the cutting process to detect potential errors or material waste before actual cutting begins.

3. Control Panel and User Interface

The control panel or user interface (UI) is where operators interact with the machine. It displays real-time data on cutting progress, machine status, and any errors that occur during operation. Modern laser cutting machines often feature touchscreen interfaces, making them more intuitive and easier to operate.

Functions:

- Real-Time Monitoring: Displays cutting progress and the current status of the machine.

- Parameter Settings: Allows operators to input or adjust parameters such as laser power, cutting speed, and material type.

- Troubleshooting: Provides alerts or diagnostic information in case of any malfunctions.

4. Software and Hardware Coordination

The software system doesn’t just control the laser head; it also coordinates other vital machine components, including the laser tube, gas supply system, and motion control system. This coordination ensures all parts of the machine work together to achieve a flawless cut.

Functions:

- Laser Tube Control: Manages the laser’s firing rate, ensuring consistency in cutting.

- Gas Flow Control: Adjusts the flow of gases like oxygen, nitrogen, or air to enhance cutting quality.

- Movement Control: Coordinates the movement of the laser head with the cutting process, ensuring accuracy and minimizing error.

5.Optimization and Intelligent Features

Modern software systems for laser cutting machines often include intelligent features that optimize performance during operation. These features are designed to improve cutting speed, reduce material waste, and enhance cut quality.

Functions:

- Path Optimization: The software calculates the most efficient cutting path, minimizing unnecessary movements and time.

- Edge Treatment: Ensures smooth, clean edges by optimizing cutting parameters, preventing issues like burn marks or rough edges.

- Parameter Adjustment: Automatically adjusts the laser power, cutting speed, and focus to match the material type and thickness.

The software system control in a laser cutting machine is essential for optimizing the cutting process, ensuring precision, and improving overall production efficiency. By effectively controlling everything from motion paths to laser power, the software ensures that the machine operates at its full potential, delivering high-quality results across various materials.

At F&E Laser Technology, we understand the importance of a powerful and reliable software control system. Our laser cutting machines are equipped with state-of-the-art software that ensures precision, efficiency, and ease of operation. Whether you’re in manufacturing, signage, or fashion design, our software-controlled systems are designed to meet your specific needs.

Contact us today to learn more about software control systems and our 3D large format software control system.