.gtranslate_wrapper

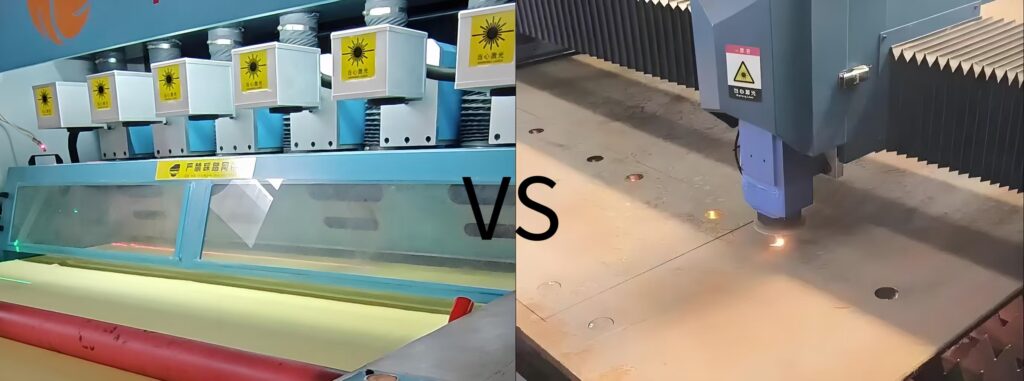

CO2 vs Fiber Laser Cutting Machines: Which One Is Right for Your Business?

In the world of laser cutting, choosing the right machine for your needs is critical to maximizing productivity, reducing costs, and ensuring the highest quality cuts. Two of the most popular options are CO2 laser cutting machines and fiber laser cutting machines. Both offer excellent precision and efficiency, but they cater to different materials and applications. In this blog, we’ll explore the key differences, pros, and cons of each type to help you make an informed decision for your business.

Whether you’re in the automotive industry, textile manufacturing, or signage production, knowing which laser cutting machine is right for your needs will improve both quality and efficiency.

1. CO2 Laser Cutting Machines: Pros and Cons

What Can CO2 Lasers Cut?

CO2 lasers use a gas laser to cut materials. These machines are especially effective when working with non-metal materials and are widely used in textile, wood, acrylic, plastic, and foam cutting. They can also handle thicker materials and offer excellent versatility.

- Materials CO2 lasers can cut:

- Wood: Ideal for creating intricate designs and signage.

- Plastic: Suitable for acrylic, PVC, and polycarbonate.

- Textiles: Popular for cutting fabrics, leathers, and textiles used in fashion and home décor.

- Foam and Rubber: Great for applications like packaging or automotive interiors.

- Glass and Stone: CO2 lasers can engrave or cut glass and certain types of stone.

Pros of CO2 Laser Cutting Machines

- Versatile Material Handling: Can cut a wide range of materials, especially non-metals.

- Cost-Effective: CO2 lasers tend to be less expensive upfront compared to fiber lasers, making them a great choice for smaller businesses or those just starting out.

- Smooth Cuts: Produces clean edges and smooth cuts, especially on non-metal materials like acrylic and wood.

Cons of CO2 Laser Cutting Machines

- Slower Speed on Metals: CO2 lasers are slower when cutting metals compared to fiber lasers, especially thicker materials.

- Less Energy Efficient: CO2 lasers tend to consume more power, which can result in higher operational costs.

- Less Precision on Thin Metals: While great for non-metals, CO2 lasers are less effective at cutting thin metals like stainless steel compared to fiber lasers.

2. Fiber Laser Cutting Machines: Pros and Cons

What Can Fiber Lasers Cut?

Fiber lasers use a solid-state laser that’s incredibly efficient and powerful. Fiber lasers excel at cutting metals like stainless steel, aluminum, and copper, making them the go-to choice for industries requiring metal fabrication or high-precision cutting.

- Materials fiber lasers can cut:

- Metal: Ideal for cutting stainless steel, aluminum, brass, and copper.

- Thin Metal Sheets: Fiber lasers provide precise cuts on thin metal sheets, making them perfect for industries such as automotive manufacturing.

- Plastics: Fiber lasers are also capable of cutting some plastics but are best suited for metals.

Pros of Fiber Laser Cutting Machines

- High Speed: Fiber lasers cut metals at a faster rate, especially when compared to CO2 lasers. This is particularly beneficial for industries that need high throughput, like automotive interiors.

- Energy Efficiency: Fiber lasers consume much less power, making them cost-effective over the long term.

- Precision: Offers extremely precise cuts on thin metals, ideal for intricate designs and high-quality outputs.

- Low Maintenance: Fiber lasers are low-maintenance compared to CO2 lasers, saving businesses on service and downtime.

Cons of Fiber Laser Cutting Machines

- Initial Cost: Fiber lasers can have a higher upfront cost, which can be a barrier for smaller businesses or startups.

- Material Limitations: Fiber lasers are optimized for metal cutting and are not as versatile with non-metal materials (such as textiles or wood) compared to CO2 lasers.

- Not Ideal for Thick Materials: While excellent for thin metals, fiber lasers are less effective at cutting thicker materials like heavy gauge steel.

3. Price Differences: CO2 vs Fiber Laser Cutting Machines

How Much Does Each Machine Cost?

- CO2 Laser Cutting Machines: Typically, these machines are more affordable than fiber lasers, making them an attractive option for businesses working with non-metal materials or those who don’t require extreme cutting precision. The price range can vary from $10,000 to $50,000 depending on the model and features.

- Fiber Laser Cutting Machines: The initial investment for a fiber laser cutter can be significantly higher, often ranging from $40,000 to $200,000 or more. However, due to their speed, precision, and lower operating costs, many businesses find that the long-term return on investment (ROI) justifies the higher price.

4. Choosing the Right Laser Cutting Machine for Your Needs

Consider Your Material Needs

- If your business focuses primarily on cutting metals like stainless steel or aluminum, a fiber laser cutting machine will provide better precision and faster cutting speeds.

- If you’re working with non-metal materials such as wood, plastics, or textiles for industries like fashion, signage, or advertising, a CO2 laser cutting machine is more versatile and cost-effective.

Industry-Specific Applications

- Automotive Industry: Fiber lasers are excellent for cutting automotive interior parts, such as trim, seats, and door panels, offering both speed and precision for high-volume production.

- Advertising: If your business focuses on custom signage or promotional products, a CO2 laser cutting machine is ideal for cutting acrylic, wood, and plastics into custom shapes.

5. Fiber vs CO2 Laser Cutting Machines – Which is Right for You?

The choice between a CO2 laser cutting machine and a fiber laser cutting machine depends on several factors, including your business’s material needs, production volume, and budget. Both technologies offer incredible benefits, but selecting the right one for your industry and applications will ensure maximum efficiency and cost savings.

- For high-speed metal cutting with low operational costs, a fiber laser cutting machine is your best bet.

- For versatility with non-metals and lower upfront costs, a CO2 laser cutting machine is a great option.

No matter which you choose, both options allow businesses to create high-quality products while optimizing their production processes.If your business focuses on non-metal materials, such as textiles, leathers, plastics, or wood, our CO2 laser cutting machines are the perfect choice. At F&E Laser Technology, we specialize in cutting flexible materials with precision and efficiency.