.gtranslate_wrapper

F&E Laser Cutting Machines: Direct from the Source Factory for Superior Quality and Precision

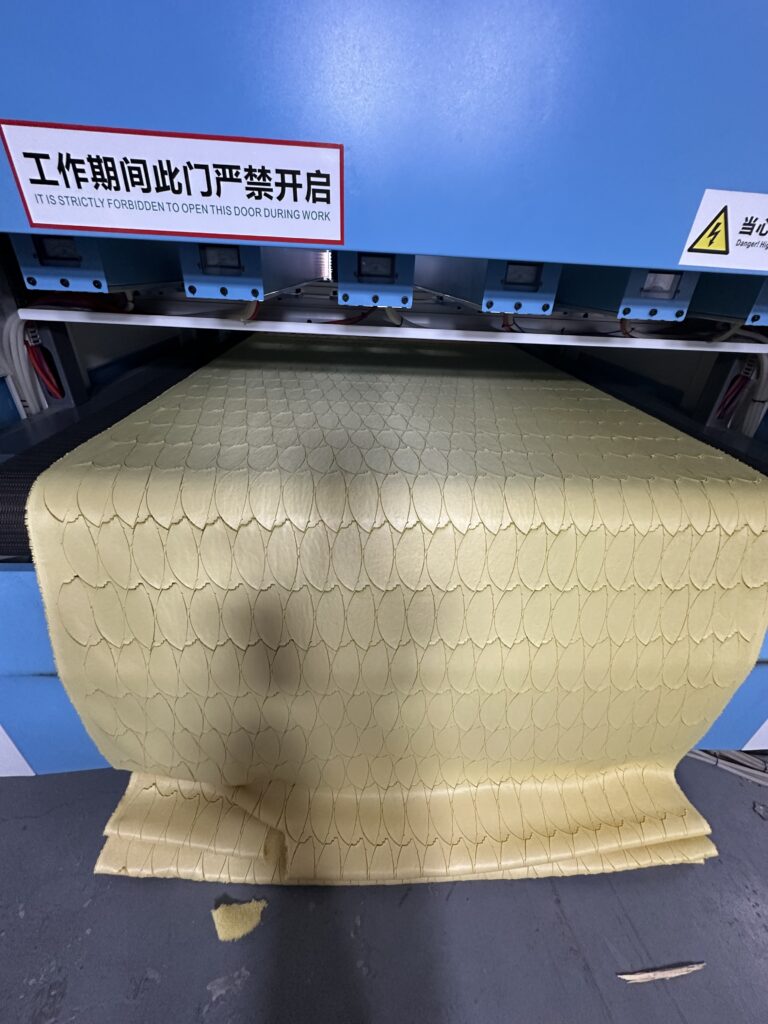

At F&E Laser Technology Co., Ltd., we specialize in providing high-quality laser cutting machines designed to meet the needs of various industries, with a particular focus on the plush toy industry. Our laser cutting fabric machines are recognized for their precision, efficiency, and ability to handle a wide range of materials. Today, we’re excited to share how our laser cutting machines are revolutionizing the production of plush toys.

Our Expertise and Technology

As a leading manufacturer based in Dongguan, Guangdong, we are proud to offer F&E Laser Cutting Fabric Machines as our flagship product. With years of experience in laser technology, we understand the intricate requirements of cutting plush fabric and are committed to delivering a solution that combines quality and precision.

Key Features and Specifications

Our laser cutting machines are designed with advanced features to ensure the highest standards of performance. Here are some key specifications:

- Laser Power: Up to 200W per laser head, with the capability of six-head lasers, offering a total power of 1200W for faster and more efficient cutting.

- Cutting Speed: Our machines offer a cutting speed of up to 1000 fabric pieces per minute, enabling high-volume production with incredible efficiency.

- Precision: The laser cutting process ensures smooth, clean, and accurate edges, essential for creating flawless plush fabric pieces.

- Cutting Thickness: Capable of cutting fabrics up to 50mm thick, making it ideal for a variety of plush materials.

- Cutting Modes: Our machines feature positioning cutting and intelligent flying cutting modes, allowing for both high precision and rapid throughput.

How It Works

The process begins with feeding the fabric into the machine’s cutting area. As the fabric moves through the system, the laser heads work seamlessly to cut along the required pattern with extreme precision. The F&E Laser Cutting Machines ensure that the edges of the fabric are free of burning or fraying, which is crucial for the plush toy industry, where fabric quality is paramount.

One of the standout advantages of using laser cutting in the plush toy industry is its ability to handle delicate and complex designs without damaging the fabric. Traditional cutting methods, such as mechanical knives or scissors, can lead to fraying and inconsistent edges, but laser cutting offers clean and precise cuts every time.

Why Choose F&E Laser Cutting Machines for Plush Toy Production?

- Efficiency: Our machines can cut large quantities of plush fabric at a rapid pace without compromising on quality. With a speed of up to 1000 fabric pieces per minute, they are perfect for large-scale manufacturing.

- Precision: The F&E Laser Cutting Fabric Machine provides flawless edge cuts, which is essential for the plush toy industry where fabric aesthetics matter.

- Cost-Effective: The high efficiency and minimal fabric wastage make our machines a cost-effective solution for both large manufacturers and small workshops.

- Versatility: Our machines are not just for plush fabric—they can handle a variety of materials, making them ideal for manufacturers of all types of textile-based products.

Industries We Serve

In addition to the plush toy industry, our laser cutting fabric machines are also perfect for other industries such as:

- Footwear Manufacturing

- Sportswear and Athletic Gear

- Medical Protective Gear

- Industrial and Protective Fabrics

High-Quality Service and After-Sales Support

At F&E Laser Technology Co., Ltd., we take pride in offering exceptional customer service. Our team is dedicated to ensuring that every client is fully satisfied, from pre-sale consultations to post-sale support. We also offer installation and training services to ensure your team is equipped to operate the machines efficiently.

Whether you’re in the plush toy industry or another textile-related sector, F&E Laser Cutting Fabric Machines provide the perfect solution for your production needs. With cutting-edge technology, fast cutting speeds, and a commitment to quality, our machines can help elevate your business to new heights.

Ready to upgrade your fabric cutting process? Contact us today to learn more about our laser cutting solutions and how they can benefit your business!