.gtranslate_wrapper

What is a Fabric Inspection Machine Used For?

Introduction: The Importance of Fabric Inspection in the Textile Industry

When it comes to the textile industry, quality control is crucial. As a manufacturer, ensuring that every fabric roll is free of defects is essential to meeting customer expectations, maintaining brand reputation, and reducing returns. But how can you ensure this level of quality without relying heavily on manual inspection? The answer lies in the fabric inspection machine—a technology designed to streamline the quality control process and enhance the precision of fabric inspection.

In this blog, we’ll dive into what a fabric inspection machine is used for, how it works, and why it’s an essential tool for businesses in the textile industry.

1. What is a Fabric Inspection Machine?

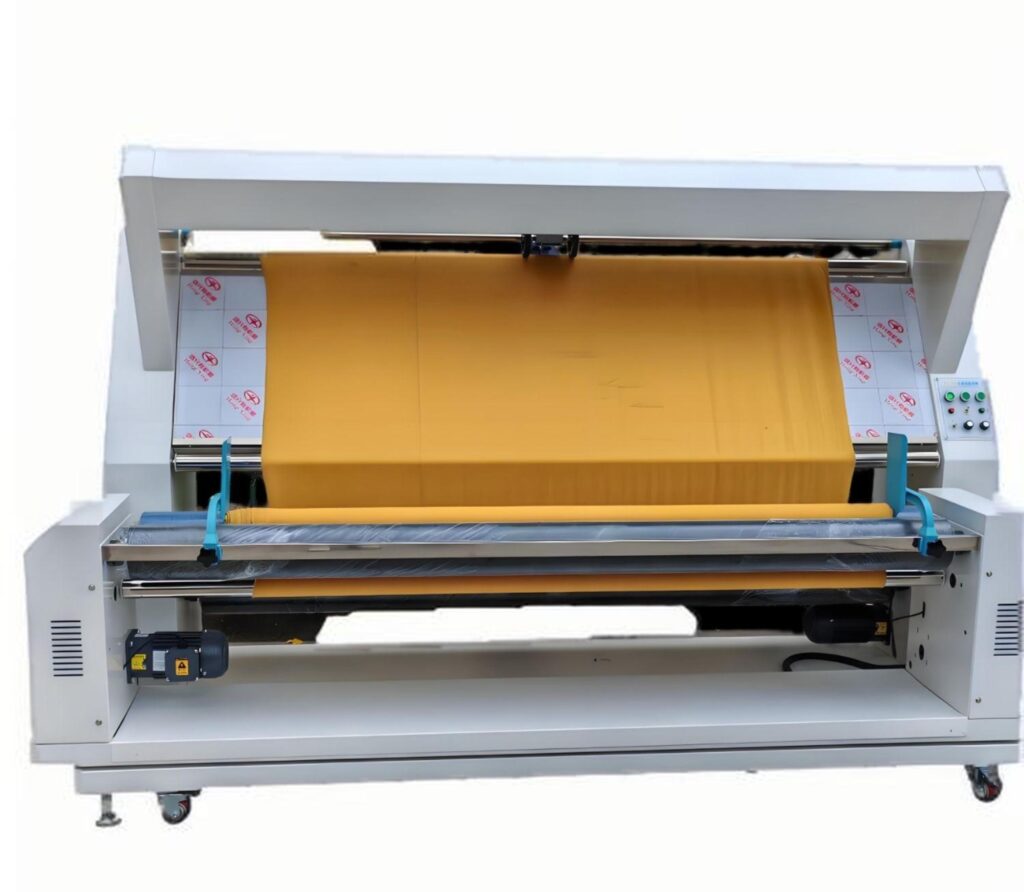

A fabric inspection machine is an automated system designed to detect defects in fabrics during the production process. It helps manufacturers identify imperfections such as tears, stains, color inconsistencies, or weaving defects that could compromise the quality of the final product. These machines are especially important for large-scale textile production, where manually inspecting every yard or meter of fabric would be too time-consuming and inefficient.

2. Key Functions of a Fabric Inspection Machine

A fabric inspection machine is used to perform several key functions in the textile production process:

Defect Detection

The primary purpose of a fabric inspection machine is to detect fabric defects. These could include:

- Visual flaws such as holes, stains, or dirt

- Weaving defects like uneven stitching, missing threads, or inconsistent patterns

- Color irregularities or fading across the fabric surface

By identifying these defects early, manufacturers can take corrective actions before the fabric moves forward in the production process, ensuring that only high-quality materials are used in finished products.

Roll Length Measurement

Another important function of the fabric inspection machine is measuring the length of fabric on each roll. The machine automatically tracks the length as it unwinds the fabric, ensuring accurate measurements for customers and preventing material wastage.

Quality Control and Consistency

A fabric inspection machine helps maintain consistent quality across fabric rolls. By continuously monitoring and checking fabric quality throughout production, businesses can meet strict industry standards and reduce the risk of costly errors in the final product.

3. How Does a Fabric Inspection Machine Work?

Understanding how a fabric inspection machine works helps highlight its importance in the manufacturing process.

Step 1: Unwinding the Fabric

Fabric is loaded onto the inspection machine, which unwinds the fabric in a controlled manner, often with the help of an automatic feeder. The fabric moves through the system, where it is laid out flat for inspection.

Step 2: Defect Detection

The fabric then passes under a high-resolution camera system or sensor that scans for defects. These machines can use optical or laser sensors to identify discrepancies in the fabric’s surface, such as inconsistent color, holes, tears, or other visible defects.

Step 3: Data Analysis and Reporting

Once the fabric passes through the scanning system, the inspection machine analyzes the data and generates a report. This report provides detailed information about the location and severity of defects, allowing operators to take immediate action if necessary.

Step 4: Automatic Roll-Up and Packaging

After the inspection is complete, the fabric is rolled back onto a new roll, typically with an automatic rolling system. In many cases, the system can also pack or label the fabric roll based on its quality, further streamlining the workflow.

4. Applications of Fabric Inspection Machines

Fabric inspection machines have a wide range of applications across various sectors of the textile industry. Here are some key industries and use cases where these machines are essential:

1. Apparel Manufacturing

In apparel manufacturing, fabric quality is paramount. Ensuring that fabric used in clothing is defect-free is vital to meeting customer expectations and reducing returns. A fabric inspection machine helps identify defects in raw fabric before cutting and sewing begins, preventing issues down the line.

2. Home Décor and Upholstery

For home décor items like curtains, upholstery, or bedding, fabric quality is crucial for aesthetics and durability. A fabric inspection machine ensures that these materials meet high standards and will stand up to frequent use.

3. Automotive and Industrial Textiles

Fabric inspection machines are used in industries that produce textiles for automotive interiors, industrial applications, and safety equipment. These applications often require fabrics to meet stringent performance and safety standards, making quality control essential.

4. Textile Printing and Dyeing

After a fabric is dyed or printed, ensuring that the final product is free of color inconsistencies or pattern misalignment is vital. Fabric inspection machines help detect these issues early, reducing the need for rework and ensuring consistent color quality.

5. Why Invest in a Fabric Inspection Machine?

For businesses in the textile industry, investing in a fabric inspection machine can offer several key benefits:

1. Improved Efficiency

Automation speeds up the inspection process, allowing businesses to inspect large volumes of fabric in less time compared to manual inspection.

2. Cost Savings

By detecting defects early, companies can avoid costly errors that could lead to material waste, product recalls, or customer dissatisfaction.

3. Higher Quality Products

With consistent defect detection, manufacturers can ensure that only high-quality fabric is used in production, leading to better finished products and fewer customer complaints.

4. Time-Saving

With automatic defect detection and roll measurement, fabric inspection machines save time on manual checks, allowing employees to focus on other tasks that require human expertise.

6. Meeting the Demands of Quality Control

In today’s competitive textile industry, ensuring that fabric is free from defects and of high quality is a key component of success. A fabric inspection machine plays an integral role in automating quality control, increasing efficiency, and delivering consistent products that meet customer demands.

If you’re looking for a reliable solution to improve the efficiency and accuracy of your fabric inspection process, investing in a fabric inspection machine is the right step to enhance production and ensure quality.