.gtranslate_wrapper

Textile Quality Control Solutions: Enhancing Production Efficiency and Product Consistency

Introduction: Why Quality Control is Essential in the Textile Industry

In the textile industry, quality control (QC) is essential to ensuring that the final product meets both industry standards and customer expectations. The ability to produce textiles with consistent quality, free from defects, is the foundation of a successful manufacturing process. In this blog, we will explore how effective textile quality control solutions can help you meet production goals, reduce waste, and maintain brand integrity.

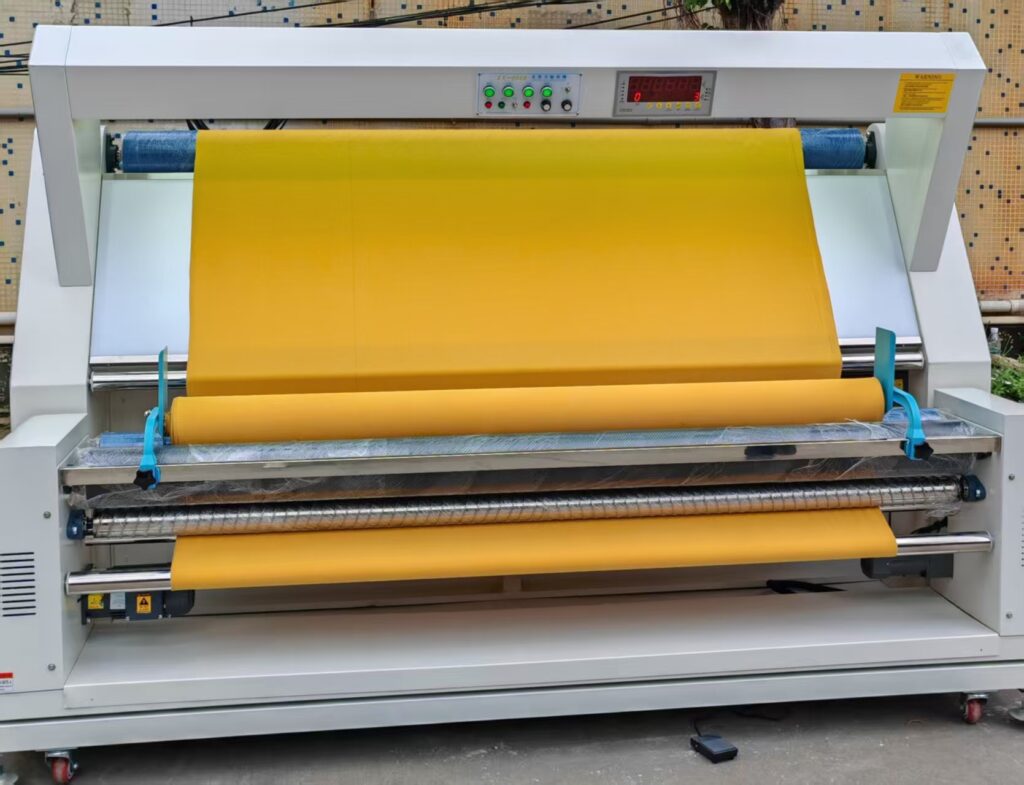

1. Automated Fabric Inspection: The Key to Precision

One of the most significant advancements in textile quality control is automated fabric inspection. Traditional manual inspection methods are time-consuming and prone to human error, leading to inconsistencies in quality and costly mistakes.

Automated fabric inspection machines offer several benefits:

- High Precision: These machines can detect even the smallest defects, such as color inconsistencies, weaving defects, or holes in the fabric, ensuring that only high-quality material moves forward in the production process.

- Speed: Automated inspection systems work much faster than manual inspection, significantly increasing throughput.

- Consistency: With automation, each fabric roll undergoes the same high-standard inspection, eliminating variability in the process.

By incorporating fabric inspection machines into your workflow, you can significantly reduce errors, lower waste, and improve the overall consistency of your textile products.

2. Tension-Free Fabric Inspection for Superior Quality

A critical feature of modern fabric inspection systems is tension-free inspection. Traditional inspection methods often distort the fabric, causing misalignment and inaccurate assessments of fabric defects.

Tension-free inspection eliminates this issue, keeping fabric flat and free from stretching, ensuring that defects are detected with perfect accuracy. This technology is particularly beneficial for:

- Delicate fabrics: Ensuring fabrics like silk or chiffon remain undamaged during inspection.

- Maintaining fabric integrity: Ensuring that no distortion occurs, which is critical for luxury textiles or custom-designed fabrics.

3. Real-Time Data Monitoring and Reporting

Today’s textile quality control solutions come equipped with real-time data monitoring and reporting. These systems allow you to track the condition of your fabric as it’s inspected, providing valuable insights into the overall quality of the production run.

- Instant feedback: Allows for immediate adjustments if any defects are found, minimizing downtime.

- Performance analytics: Helps identify patterns in fabric defects, giving manufacturers the ability to make proactive improvements in the production process.

- Traceability: Real-time reporting ensures that you can track fabric quality at each stage of production, which is crucial for compliance with industry standards.

4. Customizable Solutions for Every Production Need

Not all fabrics are the same, and neither are all production lines. The beauty of modern textile quality control solutions lies in their customizability.

Whether you’re working with woven, knitted, non-woven, or technical fabrics, modern quality control systems can be tailored to meet your specific production needs. These systems can handle various fabric types, cutting-edge materials, and intricate designs, ensuring that you get the best results for your unique product.

5. Cost Savings and Efficiency

Investing in quality control solutions isn’t just about maintaining standards—it’s also about improving your bottom line. By detecting defects early and preventing faulty materials from being processed further, textile quality control systems help you:

- Reduce material waste by catching defects before they become expensive issues.

- Minimize rework and ensure that products meet customer requirements the first time.

- Increase production efficiency, allowing your team to focus on high-priority tasks while the system handles routine inspections.

The Future of Textile Quality Control

As the textile industry becomes more competitive and customer expectations grow, having a reliable quality control system is no longer optional—it’s essential. By adopting automated fabric inspection machines, utilizing tension-free technology, and leveraging real-time data, manufacturers can enhance production efficiency, ensure consistent product quality, and ultimately deliver better results to their customers.

If you’re looking to upgrade your quality control processes, our textile inspection solutions offer the precision, efficiency, and customization you need to meet the demands of modern manufacturing.