.gtranslate_wrapper

Do you know how to maintain a laser cutting machine?

We are aware that keeping your laser cutting machine clean is only one aspect of maintenance; another is making sure it operates at its best and is safe. Numerous advantages come with routine maintenance, such as:

Improved Performance: Your laser cutting machine will run at peak efficiency if you perform routine maintenance. It makes cutting more accurate, faster, and more efficient overall.

Extended Lifespan: You can greatly increase the lifespan of your machine by giving it the proper care. Frequent maintenance reduces wear and tear, which lowers the likelihood of malfunctions and expensive repairs.

Increased Safety: Proactive maintenance helps spot possible problems early on and fix them before they become safety risks. It guarantees that your machine is operating safely, reducing the possibility of mishaps or injuries.

Decreased Downtime: By performing routine maintenance, you can find and address problems before they become serious ones. This keeps your operations operating efficiently by reducing downtime and lost output.

Cost Savings: Over time, investing in routine maintenance can result in financial savings. Early detection of minor problems can help you avoid major malfunctions that could necessitate costly repairs or the purchase of a new machine.

Regular maintenance helps keep your machine running smoothly by preventing dirt, debris, and contaminants from affecting performance. Here are some key tasks to follow:

Cleaning the device

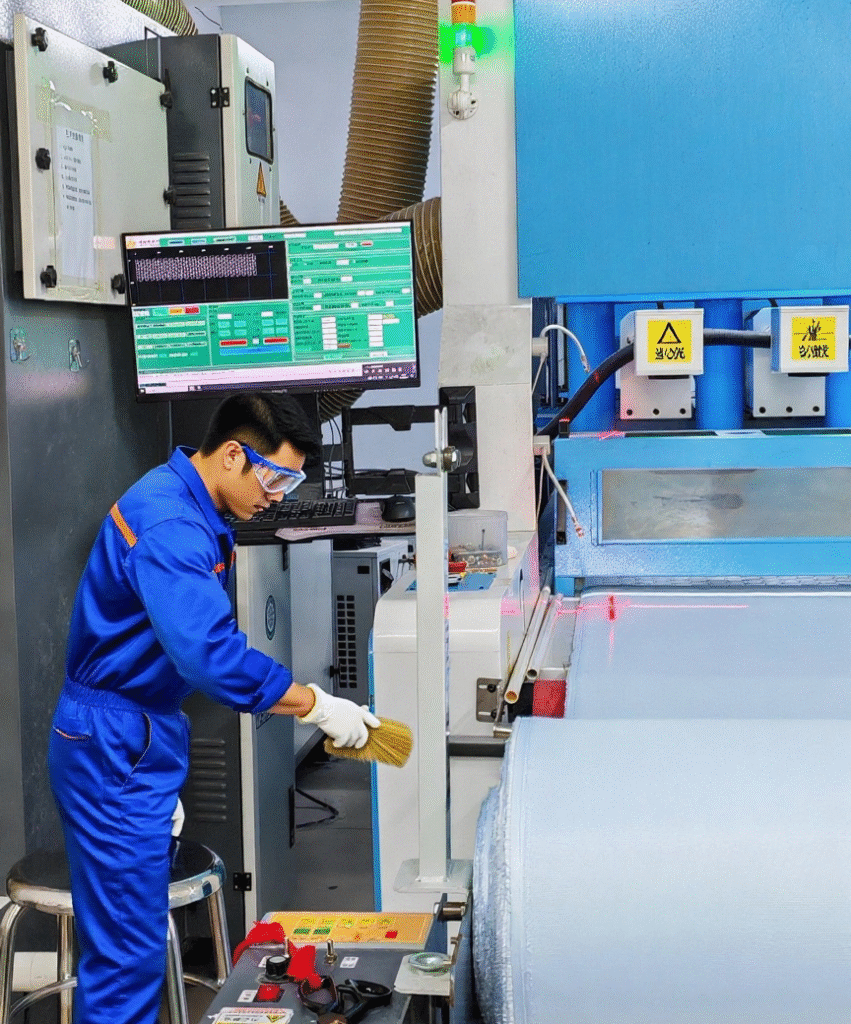

In any machine, including laser cutting machines, dust and debris are unavoidable. To get the best performance out of your machine, you must clean it on a regular basis. Examine the bed, the interior of the machine cabinet, and any other places where materials might collect. To remove any dust or debris, use a gentle brush or cloth, being careful not to scratch any surfaces.

The Fan Unit’s Inspection and Cleaning

In order to eliminate the smoke and fumes produced during the laser cutting process, the fan unit is essential. Keep an eye out for any dust or debris buildup that might impair the fan unit’s ability to operate. Use a soft paintbrush to clean the impeller fan and ducting after disconnecting the fan unit from the electrical source and removing the extraction hoses. This will guarantee adequate ventilation and avoid overheating.

Keeping the Chiller in Working Order

The chiller is in charge of keeping the laser tube at the ideal temperature and cooling it. Keep a close eye on the chiller’s operation and look for any temperature indicators on the screen. Clean the chiller’s filters and get rid of any material accumulation every few weeks.