.gtranslate_wrapper

How to Choose the Best Laser Cutting Machine for Your Business

Choosing the right laser cutting machine for your business can be a pivotal decision that affects your productivity, quality, and overall cost-effectiveness. Whether you’re just starting a new business or looking to upgrade your current equipment, selecting the best laser cutting machine is crucial to ensuring that you meet your production goals and customer demands.

In this blog, we’ll walk you through the factors to consider when selecting a laser cutting machine that suits your specific business needs. From material compatibility to machine speed, let’s explore what makes the best choice for your company.

- Identify Your Business Needs and Application

Before purchasing a laser cutting machine, it’s essential to understand the specific needs of your business and the materials you plan to cut. Laser cutting machines are highly versatile, but some models are more suited for particular industries or applications than others.

Key Questions to Ask:

What materials will you primarily cut? Metal, wood, plastic, or fabric?

What’s the thickness of the materials you need to cut?

Are you focusing on mass production or custom small-batch jobs?

Material Compatibility:

CO2 lasers are excellent for cutting non-metal materials like wood, plastics, leather, and fabric.

Fiber lasers are designed to cut through metals, such as stainless steel, aluminum, and brass, with high precision and speed.

By understanding your business needs, you can choose a laser cutting machine that’s best suited to the materials and applications you work with.

- Consider the Cutting Speed and Precision

Speed and precision are key factors that directly affect your production efficiency and the quality of the cut. If your business relies on quick turnaround times or high-volume production, you’ll need a machine that balances both speed and precision.

Key Factors:

Laser Power: Higher wattage lasers provide faster cutting speeds and are better for cutting thicker materials.

Precision: A high-precision laser cutter ensures your designs are accurately reproduced with minimal waste.

Cutting Speed: The faster the machine, the quicker you can produce parts and fulfill orders. However, speed should not come at the cost of precision.

For businesses that require detailed, intricate cuts (e.g., jewelry design or prototyping), precision should be a higher priority. On the other hand, for mass production of simple shapes, speed may take precedence.

- Machine Size and Bed Capacity

Laser cutting machines come in various sizes, so choosing one with an appropriate bed size is critical for your production capacity. The bed size refers to the maximum dimensions of the material that the laser cutter can handle.

Considerations:

Small Businesses: If you’re operating on a smaller scale, a compact machine with a smaller bed size might be more suitable.

Larger Production Runs: For high-volume production or cutting larger materials, you’ll need a machine with a larger cutting bed to accommodate larger workpieces.

Additionally, consider the footprint of the machine, ensuring that your workspace can comfortably fit the laser cutter.

- Evaluate the Machine’s Ease of Use and Software Integration

Ease of operation and seamless software integration are crucial to minimizing training time and improving workflow efficiency. A user-friendly interface makes it easier for your team to operate the laser cutter, saving you both time and money.

Key Features to Look For:

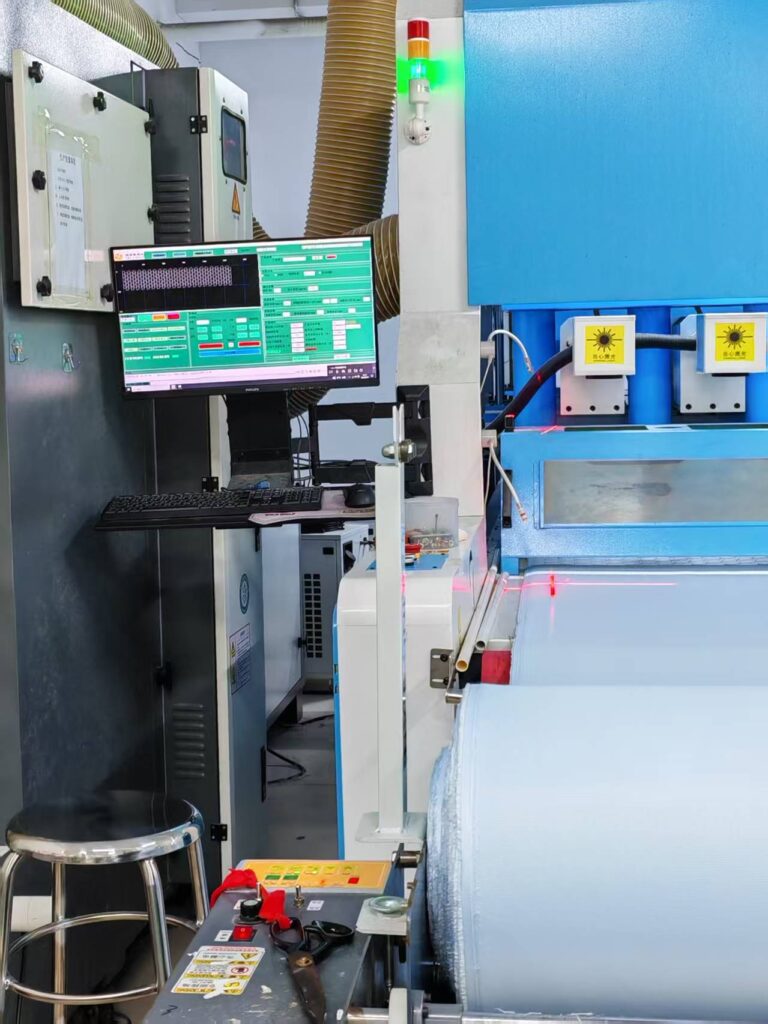

User Interface: Look for a machine with an intuitive touch screen or easy-to-use control panel that makes setup and operation simple.

Software Compatibility: Ensure that the machine is compatible with popular design software, such as AutoCAD, CorelDraw, or Adobe Illustrator.

Job Management Software: Some laser cutting machines come with software that helps you manage cutting paths, optimize material usage, and track production progress.

Having software that integrates well with your existing systems can significantly improve workflow efficiency and reduce operational errors.

- Maintenance and Support

A laser cutting machine is a long-term investment, so it’s essential to understand the maintenance requirements and the level of after-sales support provided by the manufacturer.

Key Considerations:

Maintenance: Look for machines that require minimal maintenance or come with features that help extend the life of the machine (e.g., self-cleaning systems).

Spare Parts and Support: Ensure that the manufacturer offers good customer service and has readily available spare parts. A solid warranty can also provide peace of mind.

Training and Setup: Does the manufacturer provide installation and operator training? This can make a huge difference in getting your team up to speed quickly.

- Budget and Return on Investment (ROI)

Finally, while it’s tempting to choose a cheaper machine to save costs, it’s important to consider the long-term value of your investment. Choosing a machine that meets your needs can result in higher efficiency and quality, leading to greater profits in the long run.

Factors to Consider:

Initial Cost vs. Efficiency: A more expensive, high-performance machine may reduce the need for repairs and downtime, leading to better ROI.

Operating Costs: Evaluate power consumption, material waste, and maintenance costs. Efficient machines may have a higher upfront cost but save money over time.

Production Speed: Faster cutting speeds can help increase throughput and reduce labor costs, ultimately improving your bottom line.

Choosing the best laser cutting machine for your business requires careful consideration of your specific needs, including the materials you plan to cut, the precision required, machine size, and ease of operation. At F&E Laser Technology, we provide custom laser cutting solutions tailored to your business, with machines that offer both precision and speed to meet your unique production goals.

If you’re ready to take your production to the next level with advanced laser cutting technology, contact us today to discuss your needs and discover the perfect laser cutter for your business.