.gtranslate_wrapper

LASER

Laser system calibration, beam optimization, scanning upgrades

OUR LASER

The Jieyimei Service team always puts our clients’ needs above our own from the initial consultant stage through to the installation and start-up of the laser system. Ensures continuous follow-up for optimal laser potential.

With 20 years of experience in the laser industry, Jieyimei has developed a deep understanding of materials and their applications. The technical skills and dedication of MimoWork play a key role in ensuring reliable operation of our laser machines so that a Jieyimei customer always feels unique.

Find out how Jieyimei delivers services:

Jaeden Higgins

“Thanks to Jieyimei Laser and the technical team, our project has benefited from the precise performance of metal resistance elements.

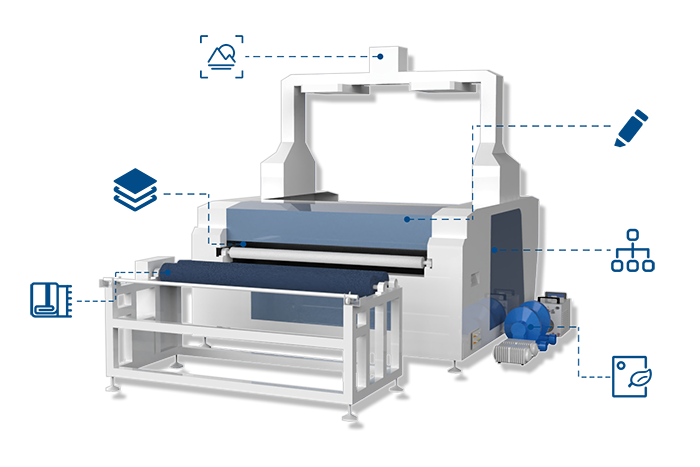

How our laser machines work

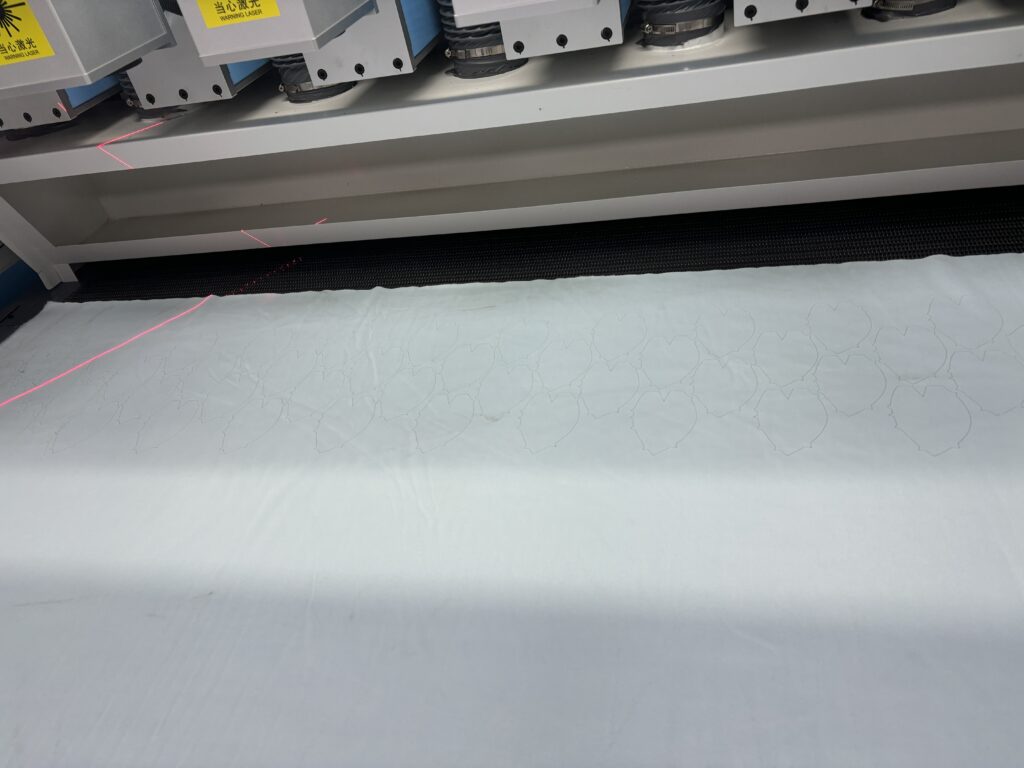

Feeding system

Engineered for Precision Performance

Seeking to ensure your plush toy laser cutting projects start flawlessly? Our machine is the first step in the process. It smooths and straightens fabric, feeding it into the laser cutter wrinkle – free.

We use advanced equipment to prep materials. Just like how X – ray tech verifies internal components in precision manufacturing, our fabric – flattening machine ensures a perfect, crease – free surface. This sets the stage for accurate, high – quality laser cutting—critical for detailed plush toy designs.

- Precision Fabric Prep — Smooth, even material for laser cutting accuracy.

- Consistent Results — Reliable flattening to avoid defects in final plush toys.

- Custom Solutions — Adaptable to different plush fabric types and project needs.

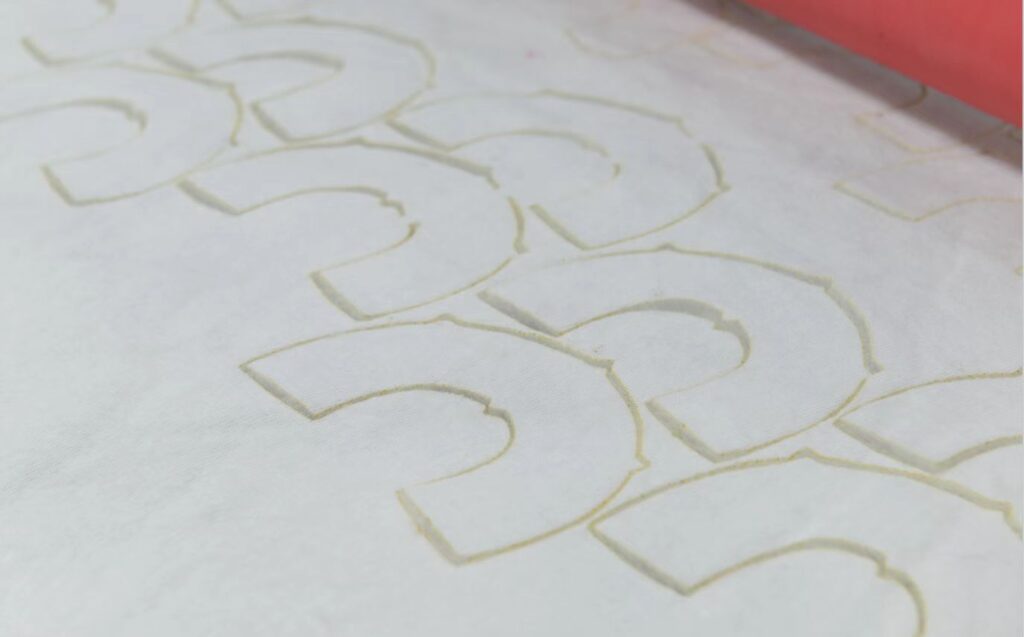

Visual system

Precision Engineered for Reliability

When it comes to plush toy laser cutting, we’ve got the process down to a science. After the fabric is prepped to be smooth and wrinkle – free, the second step is where the magic of cutting happens with our F&E LASER machine.

Our well – planned workshop layout houses a specialized production line for plush toy laser cutting. This setup enables fast and highly efficient production. Our team, with expertise adapted to plush toy manufacturing needs, focuses on delivering precise laser – cut plush toy parts. Whether it’s standard – size plush components or custom – designed, intricate toy shapes, we ensure top – notch results.

- Dynamic Cutting: Ideal for large – volume cutting of plush fabrics. It can swiftly handle big batches, ensuring consistent cuts for mass – produced plush toys.

- Static Cutting: Perfect for more detailed, smaller – scale or custom plush designs, where precision in every cut matters.

Engineered for Precision Performance

Crafting plush toys? Precision in cutting is everything. After prepping and cutting, our final step delivers flawless, 1:1 – cuts for your designs.

We use advanced tech (like X – ray inspection adapted for plush quality checks) to ensure every detail shines. Whether it’s intricate shapes or large – scale patterns, our laser cutting guarantees:

✅ Precision Manufacturing — Sharp, accurate cuts that match your design down to the millimeter.

✅ Consistent Quality — No frays, no errors—just clean, perfect edges for plush toys.

✅ Custom Solutions — From unique prototypes to bulk production, we nail every detail.

See the difference in our finished plush cuts? Ready to bring your designs to life with 100% precision?

Cooling system

Precision Engineered for Reliability

Laser cutting generates intense heat – but we’ve got you covered. These dedicated cooling machines precisely manage thermal buildup during the process, maintaining optimal operating temperatures. With advanced temperature regulation, they eliminate overheating risks, ensuring a safe, stable workflow while safeguarding cutting accuracy. No thermal stress on equipment, no safety hazards – just smooth, controlled production from start to finish.

Pre-Sales Consultant

Certain industries present unique challenges when it comes to processing advising. For...

Material Testing

Material is what you need to pay the most attention to. You can find the laser ability of most...

Training

Your competitiveness is not only affected by the laser machines but also driven by yourself. As you...

Installation

The installation of any machinery is a decisive phase and must be carried out correctly and in the...

After-Sales

After your purchase, MimoWork will provide the customers with our full-range service and get...

Spare Parts

Jieyimei is committed to providing you with the best standard spare parts. As long as...

Extended Warranty

Jieyimei is dedicated to design and produce long-lifespan laser machines to boost their...

On-site Services

Jieyimei backs our laser machines with general on-site services including installation...

Choose A Reliable Manufacturer

Choose A Reliable Manufacturer

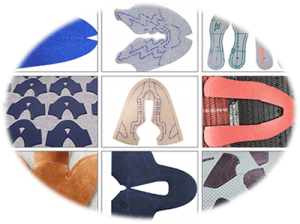

Looking for a competitive – edge, fast – turnaround supplier for your plush toy laser cutting project? Jieyimei excels in plush toy laser cutting in China, handling both prototypes and end – use plush toy parts.

We offer a comprehensive range of plush toy laser cutting services. Our advanced laser cutting technology ensures precise cutting of various plush materials, achieving intricate designs and clean edges. With an ISO 9001 – certified production process, combined with professional experience and state – of – the – art laser cutting machines, we guarantee that your plush toy parts are crafted perfectly, every single time.

Customers We Serve

Jieyimei provides top – notch global services and has a large, rapidly expanding customer base. Our customers are worldwide and from diverse industries. It ranges from independent toy inventors or designers to large – scale Toy, Retail, and Entertainment companies. We’ll always strive to meet your plush toy design and manufacturing needs, and bring your creative plush toy ideas to life.

Factory Display

Quality - Driven Sample and Certification Processes

Why choose us?

Processing capacity

Our strong production capabilities enable us to meet all of your project requirements from prototype to production.

On time delivery

We value and understand the importance of on-time delivery, so we will make a suitable production plan for your project.

Excellent experience

Our experts will assist you and respond to your inquiries promptly, bringing you an exceptional customer experience.

What services can we provide

Short Delivery Time: With a physical factory, we have strong production capacity and sufficient inventory.

Adequate Capacity: We reject false labeling and ensure rated capacity.

Authoritative Certification: Passed various authoritative certifications, meeting international standards.

Customizability: Dimensions, capacity, protection board, and other requirements can be customized according to customer needs.

Quality Assurance: We build a comprehensive quality system from parts to finished products to ensure product quality.

Perfect Service System: We respond quickly to customer questions and provide solutions.

Provide convenience for your post-processing

- Accurate materials labeling by digital control

- Ideal for shortening subsequent sewing or alignment

- Various materials can be marked onto

- Available for different colors and shapes

Using marker pens and inkjet options, you can mark workpieces to simplify subsequent production. Especially in the case of sewing marks (cutting) in the textile manufacturing sector. For example, in the use of cutting filter cloth, selecting mark pen or ink-jet to mark the alignment lines directly on the piece, saving time and difficulty in subsequent operations.

Our Value

Professional

Means doing what's right, not what's easy. With this spirit, Jieyimei also shares laser knowledge with ourcustomers, distributors, and staff group. You can check our technical articles regularly on Jieyimei-Pedia.

International

Jieyimei has been a long-term partner and laser system supplier for numerous demanding industrial companies on a worldwide basis. We invite global distributors for mutually beneficial business partnerships. Check our Service details.

Trust

Is something we earn every day through open and honest communication and by putting our clients’ needs above our own.

Pioneering

We believe that expertise with fast-changing, emerging technologies at the crossroads of manufacture, innovation, technology, and commerce are a differentiator.